Prefabricated-running-track

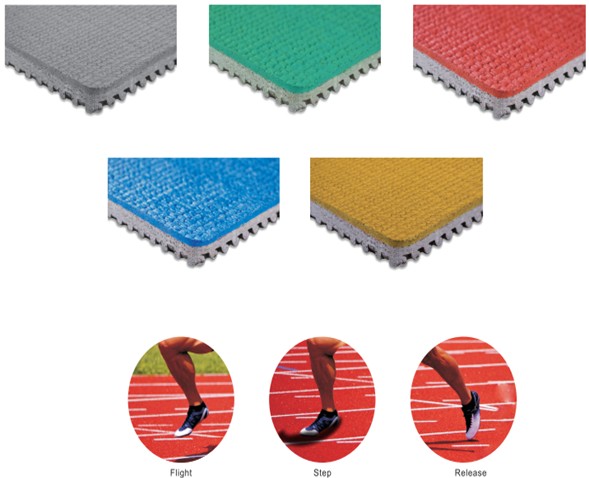

prefabricated track is a prefabricated rollsheet specially designed for competitive athletic performance. For competitive performancethe track surfaces are made of natural and synthetic rubbers of pressing process for synchronized shaping emboss and vulca

Prefabricated track systems are designed for all levels of training and competition at high intensity use facilities and they are the preferred track surface for wheelchair athletes and is extensively used at Major Track & Field Championships (a prefabricated track surface was used at the London 2012 Olympic and Paralympic Games). Whilst they are more expensive to install than other track systems they tend to be much harder wearing and require less maintenance and remedial repairs.

The mat is adhered to a base macadam to provide a non-porous system. Like solid and sandwich systems this type of surface is also impermeable to water and relies on crossfall to slot drains to keep the running surface free of surface water. This method of track construction produces excellent finish levels to exacting standards and is recognised as a elite level surface suitable for international athletics events.

Prefabricated tracks tend to be more long lasting and have lower maintenance costs than polymeric surfaces and retain their performance characteristics throughout the life of the material. There are also environmental benefits in that prefabricated systems can be removed and recycled.

|

IAAF Test Results |

|||||

|

Test item |

Mpa |

Reference IAAF |

Standard |

Test data |

Judge |

|

Elongation at break |

% |

IAAF |

≥40 |

134.0 |

≥200% |

|

Force Retardance |

% |

IAAF |

35-50 |

40.4 |

≥49BPN20"C |

|

Vertical deformation |

1m |

IAAF |

0.6-2.5 |

1.61 |

1.2min |

|

Skid resistance |

BPN20'C |

IAAF |

≥47 |

47 |

0.18mm |

|

Flame Retardance |

|

GB/T14833-2011 |

|

|

UV531 |